NSEA-SR-145 (North Sea)

CHALLENGE

A major operator on the Norwegian Continental Shelf needed to release the annular safety valve (ASV) of a well for later completion string retrieval but were concerned about scale buildup. Normally they would use string shots and brushes to remove scale, or, they would cut the tubing & the ASV.

They elected to try BLUESPARK® pulsing technology to remove the scale instead, as BLUESPARK® can more accurately target specific depths and would save both time and cost.

SOLUTION

Remove scale from the upper completion of the wellbore using electro-hydraulic pulsing technology.

The BLUESPARK® tool was run on third-party E-Line to the treatment interval.

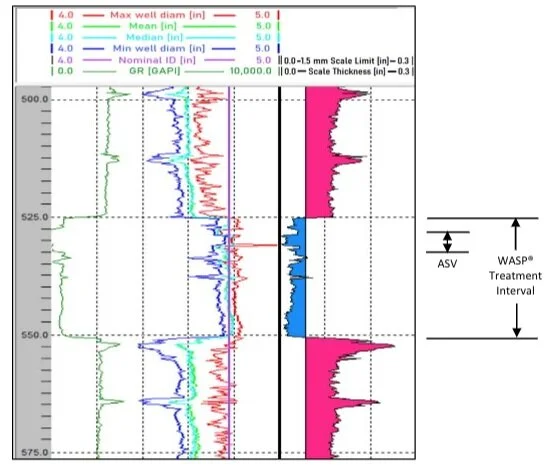

A 25 m interval was treated across the ASV and below it, thereby exposing the internal “punch tool locator” profile and clearing an area for plug installation.

The treatment was completed in one run in less than 14 hours of operating time.

A multi-finger caliper (MFC) was run over the treated and untreated sections of the wellbore for comparison to the previous caliper log.

CONDITIONS

Depth: 525 m (1,720 ft)

Temperature: 40 °C (104 °F)

OUTCOME

The MFC log confirmed that the scale over the interval treated had been reduced by 80 – 100%.

The plug was set below the ASV and the ASV was released with a dedicated punch tool.

BLUESPARK® saved up to 5 days of operating time and USD 200K.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.