SSA-SR-139 (West Africa)

CHALLENGE

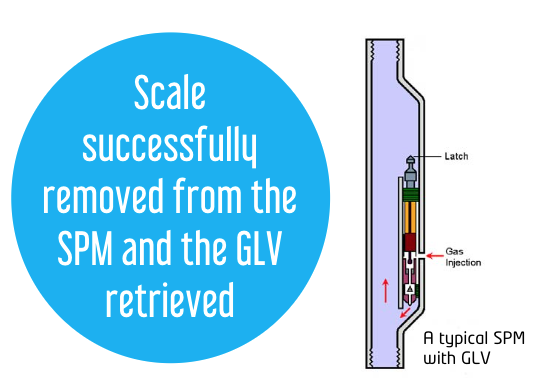

The well of a major operator in Equatorial Guinea was slugging and required a replacement of the Gas Lift Valves (GLV). It had been noted that scale was present during previous interventions. Acid was considered, but injectivity could not be established. A roller brush could not be deployed either, as the inclination of the GLM/GLV was too high.

SOLUTION

Clean scale from the Side Pocket Mandrels (SPMs) to help retrieve the GLVs using electro-hydraulic pulsing technology.

The BLUESPARK® tool was run on third-party E-Line using a wireline tractor for conveyance into a highly deviated section of the well.

The lower SPM was treated followed by the upper SPM on the same run in the hole. The lower SPM was known to have scaling issues.

For both SPMs, the orientation sleeve, the GLV latch area, and the GLV gas orifice were all treated.

A tractor/stroker run was made to retrieve the GLVs.

CONDITIONS

Depth: 6,000 ft MD (1,830 m)

Temperature: 60 °C (140 °F)

OUTCOME

Before running BLUESPARK®, three attempts were made with a wireline tractor/stroker combination to retrieve the GLVs, but none were successful.

After only one treatment of the SPMs with BLUESPARK®, the tractor/stroker tool was able to retrieve both GLVs on the first attempt. For the lower SPM, this was due to the ability of BLUESPARK® to clear scale from the orientation sleeve and complex shapes like the GLV latch.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.