NSEA-SR-131 (North Sea)

CHALLENGE

A Major North Sea operator requires scale-free sections of tubing for plug set and tubing cut prior to pulling the completion. Calcium carbonate scale (CaCO3) forms inside the tubing and is very difficult to remove using mechanical or chemical methods. This objective was previously achieved from a jack-up rig using coiled-tubing and jetting technology (fluids & abrasives).

The operator had previous success using BLUESPARK® to remove scale from other completion hardware, so decided to use BLUESPARK® to clean sections of the tubing.

SOLUTION

Remove CaCO3 scale from sections of tubing using electro-hydraulic stimulation technology.

The BLUESPARK® tool was deployed on the operator’s preferred wireline provider’s E-Line from the platform, prior to the jack-up’s arrival.

A Fluid Hold-Up Tool (FHUT) was used to maintain a fluid column over the toolstring.

Two 20 foot intervals (6 m) were treated in one wireline run in less than 4 hours of treatment time. Total operating time was 48 hours.

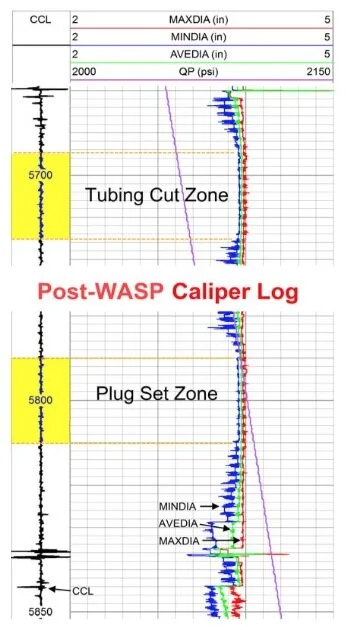

A caliper log was performed on wireline to verify the scale removal.

CONDITIONS

Treatment Depth: 5,800 ft (1,770 m)

Treatment interval @ 30° deviation

OUTCOME

The caliper log confirmed that the BLUESPARK® had completely removed the CaCO3 scale from the inside of tubing over the two treated sections.

The plug was successfully set and pressure tested, followed by a successful tubing cut, both in the zones treated by BLUESPARK®.

Coiled Tubing was not required, eliminating the cost of that service – mobilisation, rig-up, rig-down and reduced crew.

Reduction of 8 days of jack-up rig time, as the BLUESPARK® operation was performed offline.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.