NSEA-SR-135 (North Sea)

CHALLENGE

A major North Sea operator had a SSSV that had been inoperable and the well had been shut in for several years. The SSSV flapper was stuck in a partially open position and it would not close or pass an inflow test.

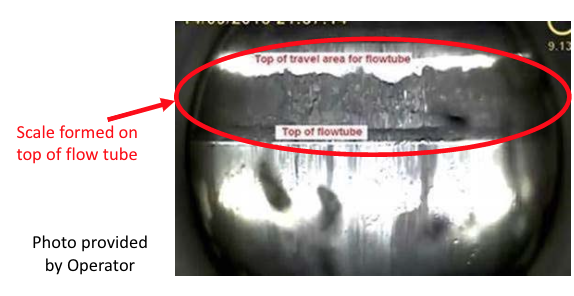

There was also a Wireline brush stuck below the SV flapper at an unconfirmed depth. Calcium Carbonate scale was seen in the flow tube area and in the tubing above the SSSV.

SOLUTION

Remove CaCO3 scale from the SSSV to restore functionality using electro-hydraulic pulsing technology.

The BLUESPARK® tool was run on third-party E-Line with a No-Go so as not to contact the flapper.

The flow tube was cleaned during the first run in the well (the flow tube was now moving).

The No-Go was removed and a second run was made to treat the flapper directly, as well as the entire length of the SSSV.

CONDITIONS

Depth: 550 m (1,800 ft)

OUTCOME

An increase in control line returns was noted after the 1st BLUESPARK® run, indicating the flow tube and flapper were reactivated.

A successful inflow test was performed on the SSSV after the 2nd run.

Subsequently, the Wireline Brush was fished from beneath the SSSV, the well was perforated in 2 new zones and brought back online.

Production was commenced after being shut-in for several years.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.