NAM-SR-136 (Canada West)

CHALLENGE

A customer operates a Cyclic Steam Stimulation (CSS) field with some wells experiencing reduced production due to CaCO3 scale buildup. The client chose Well #4 on a particular pad for treatment with symptoms that included a ΔP of over 1 MPa, 40% plugging on the steam-throttle-joint (STJ) curve, and poor gross production vs DI performance compared to the average.

The customer chose BLUESPARK® for the treatment as there would be no damage to any completion equipment, maintaining well integrity.

SOLUTION

Improve connectivity to the reservoir by removing CaCO3 scale and clearing out blockages using electro-hydraulic stimulation technology.

Well #4 was cooled by pumping warm water down the liner to cool the wellbore to below 130 °C.

The BLUESPARK® tool was conveyed on third-party e-Coil to the toe of the wellbore.

There were 21 distinct intervals of 1.0 m treated as the toolstring was pulled up the wellbore towards the heel.

The field was then switched from CSS to steamflood, and Well #4 was monitored, along with 4 other wells on the same pad that were not treated with BLUESPARK®.

CONDITIONS

Measured Depth: 2,000 m(6,600 ft)

Clearwater shale

OUTCOME

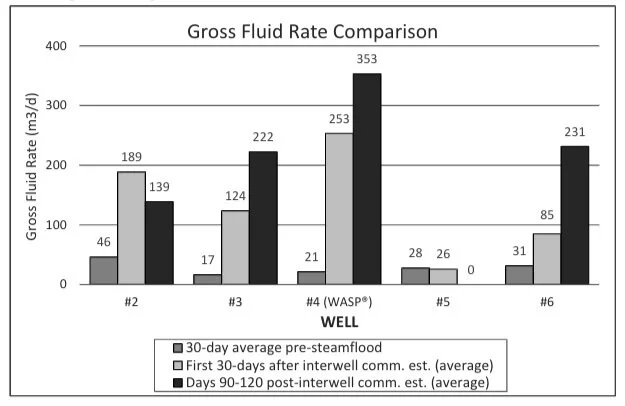

Well #4 (BLUESPARK® treated well) achieved a quicker and higher ramp up in production.

After factoring in flush production and incremental fluid production due to reservoir pressure communication, the client calculated there was an additional 60 m3/d of sustained gross fluid production for Well #4 vs the other wells on the same pad.

Well #4 had a 90% higher rate in the first 3 months vs the other wells*, and a 79% higher rate in the 90-120 day post interwell communication established period.

*Average, not including well #5

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.