NAM-IW-133 (Canada West)

CHALLENGE

The operator’s disposal wells are completed in a very unconsolidated sand and have an ongoing problem with the sand generating large amounts of fill in the wellbore, often covering portions of the completed zone. Due to liner size restrictions, reperforating and installing a screen is not an option.

They will sometimes bail out the sand, but decided to try BLUESPARK®, which is more cost effective, and could clear blockages in the open portion of the completion.

SOLUTION

Improve connectivity to the reservoir by clearing sand screen blockages using electro-hydraulic stimulation technology.

The operator chose two wells with poor injectivity to treat with BLUESPARK®.

Both wells were treated through tubing with the BLUESPARK® slim-hole tool on third-party E-Line.

The treated intervals were 15 m and 26 m, taking just 5 hours and 8 hours respectively of treatment time.

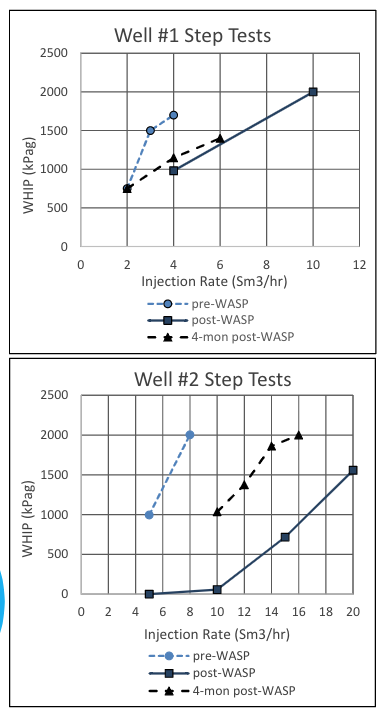

The wells were put back on injection and monitored. Several step rate tests were done to confirm injectivity rates.

CONDITIONS

Depth: 300 m (1,000 ft)

McMurray sandstone

OUTCOME

Both wells saw an immediate drop in injection pressure resulting in an increase in injection rate.

Step rate tests done immediately after the treatment and after several months confirmed lower pressures and higher injection rates than before the treatment were being maintained.

The comparison of total volume injected for 6 months pre- and post-treatment showed a 23% increase for Well #1 and a 179% increase for Well #2.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.