NAM-PW-112 (USA Permian)

CHALLENGE

Client is operating a mature asset in the Permian Basin and were experiencing lower than expected production rates from several wells in an oilfield. Conventional remediation techniques, such as acid treatments, resulted in short term improvements that typically required subsequent re-treatments. Client was willing to try a unique technology as an alternate way to improve near wellbore permeability.

SOLUTION

Improve connectivity to the reservoir using electro-hydraulic stimulation technology.

In Q1 of 2014 the client chose to apply the BLUESPARK® treatment during a regularly scheduled workover.

BLUESPARK® was deployed into each well, with one well being treated per day.

Production tubing and the artificial lift were re-installed in each well and the client resumed monitoring the production rates, pressures and fluid levels, reporting the continued success to Blue Spark Energy.

CONDITIONS

Depth: 3,800 FT (1,150m)

Grayburg Dolomite

OUTCOME

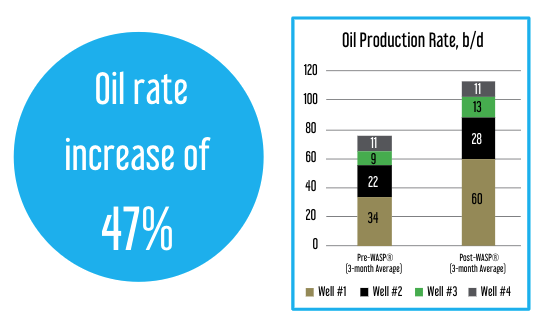

Client data from the BLUESPARK® treated wells showed an aggregate production increase of 47% for the 4 wells over a 3 month period (from 76 b/d to 112 b/d).

By applying the BLUESPARK® treatment during regular workovers, the application was efficient and the incremental cost was low when compared to other types of remediation.

The BLUESPARK® treatment has been longer lasting than other forms of near-wellbore remediation. The client continues to monitor results in order to determine the longevity of our treatments.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.