NAM-PW-114 (USA California)

CHALLENGE

Client experienced significant reduction in well production due to a near wellbore impairment, in this case, organics and fines. Conventional treatments, such as acid stimulation, had yielded mixed or short term results over the past couple of treatment candidates. Client was willing to evaluate a novel technology to solve near wellbore formation damage issues in the reservoir, as an alternative remediation technique.

SOLUTION

Improve connectivity to the reservoir in gravel pack applications, using electro-hydraulic stimulation technology.

Applied BLUESPARK® technology in select trial wells, in thermal heavy oil pool.

Treated gravel pack production interval with pulsing technology at 5 minutes per foot (16 minutes per meter).

Evaluated post-stimulation production rates, reservoir temperature and bottom hole pressures, to compare to pre-treatment values.

Customer elected to preform BLUESPARK® trial in 8 wells.

CONDITIONS

Depth: 820-950 ft (250-290 m)

Temperature: 212 °F (100 °C)

OUTCOME

The customer observed the following:

Oil production in 3 trial wells was over 4x greater after stimulation (3-month comparison).

An increase in both oil cut and well temperatures was observed in the majority of the trial well.

Additionally, the client observed that electro-hydraulic stimulation provided greater longevity and higher production rates, when compared to conventional acid stimulation results.

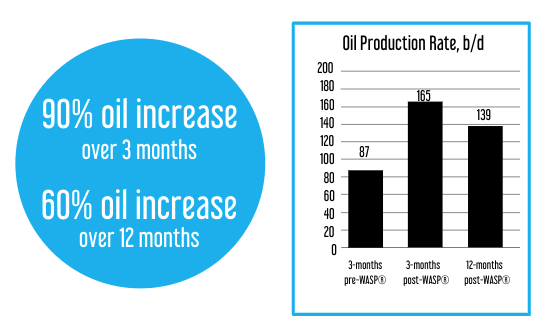

Oil production for the 8 trial wells increased from 87 to 165 b/d for the first 3-months; the 12-month average was 139 b/d.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.