NAM-PW-126 (USA Mid-Continent)

CHALLENGE

The client’s well was fracked when it was completed, and flowed as high as 900 MCF/d of wet CBM gas. Within 2 years, the gas production rate had dropped by 75%. Several acid treatments were done over the next few years, usually resulting in an increase from 50% – 100% that would last 2 to 4 months. The client decided to try a BLUESPARK® treatment to see if better results could be obtained.

SOLUTION

Improve connectivity to the reservoir by clearing out blockages using electro-hydraulic stimulation technology.

The wellbore was cleaned by a bit & scraper run.

The BLUESPARK® tool was run on third-party E-Line to the perforated intervals.

Four perforated intervals of 20 ft total (6 m) were treated in less than 8 hours of total operating time with our wireline conveyed tool to improve flow through the formation rock.

The well was put back on production and monitored.

CONDITIONS

Depth: 4,700 ft (1,430 m)

Ferron coal-bearing sandstone

OUTCOME

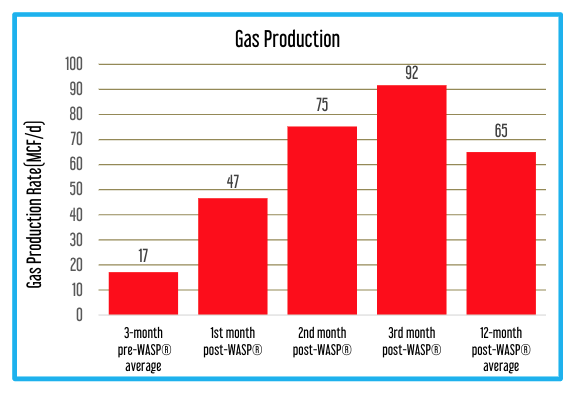

The well saw an immediate increase in gas production, which continually rose over the next 3 months.

The average gas production increased from 17 MCF/d to 71 MCF/d in a 3-month comparison, an increase of over 300%.

The average gas production for the 12-months post-BLUESPARK® was 65 MCF/d, a 280% increase over the pre-BLUESPARK® rate.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.