NAM-IW-125 (Canada West)

CHALLENGE

The client operates 200 wells in a field, with only two water injection wells being used to maintain pressure in one portion of the field.

Both wells suffer from near-wellbore damage due to scale and suspended solids. To treat the problem, acid stims were conducted every 6 to 8 months, but with diminishing rate of returns. The client was looking to reduce workover frequency and to increase injection rates.

SOLUTION

Improve connectivity to the reservoir by removing blockages using electro-hydraulic stimulation technology.

The BLUESPARK® slim tool was run through tubing on third-party E-Line, avoiding the need to pull tubing.

The perforated interval was 8.5 m in length and the stimulation was completed within an operating time of 5 hours.

BLUESPARK® cleared the blockages in the formation to provide more surface area for a chemical treatment to be more effective.

A mixture of solvent and acid was batched down the tubing of the well which was allowed to soak overnight.

The well was put back on injection and monitored.

CONDITIONS

Depth: 1,800 m (5,900 ft)

Temperature: 60 °C (140 °F)

Montney formation

OUTCOME

The well saw an immediate increase in injection rates and a decrease in injection pressure.

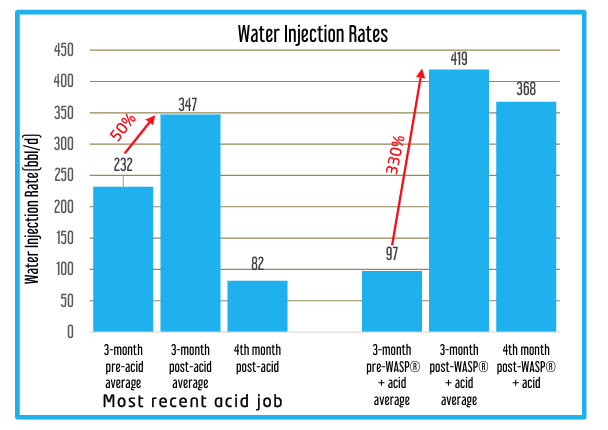

The average injection rate increased from a 3-month average of 97 b/d to 419 b/d for the first 3 months after BLUESPARK® + Acid.

The increase was over 330%, compared to a 50% increase over 3 months for the last treatment done with acid alone.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.