NAM-IW-118 (Canada West)

CHALLENGE

Well had initially been a producer for 8 years and then was converted to an injector. Over the next 40 years, the well was re-perforated twice due to declining injection rates. After the second re-perf, the injection rate declined gradually for 10 years.

After being shut-in for almost 2 years, the client decided to try a different type of technology to obtain better, longer lasting results.

SOLUTION

Improve injectivity into the reservoir by clearing out blockages using electro-hydraulic stimulation technology.

Sandstone reservoir was treated with BLUESPARK® to improve injectivity.

No special tools or equipment were required on location to complete the remediation operation, other than third party E-Line.

Approximately 13 m (42 ft) of perforated interval were treated with our wireline conveyed tool in one working day.

Injection rates and pressures were both monitored for comparison to pretreatment values.

CONDITIONS

Depth: 1,000m (3,300ft)

Sandstone

OUTCOME

The wellbore was reconnected to the reservoir, as pressures decreased and injection rates increased.

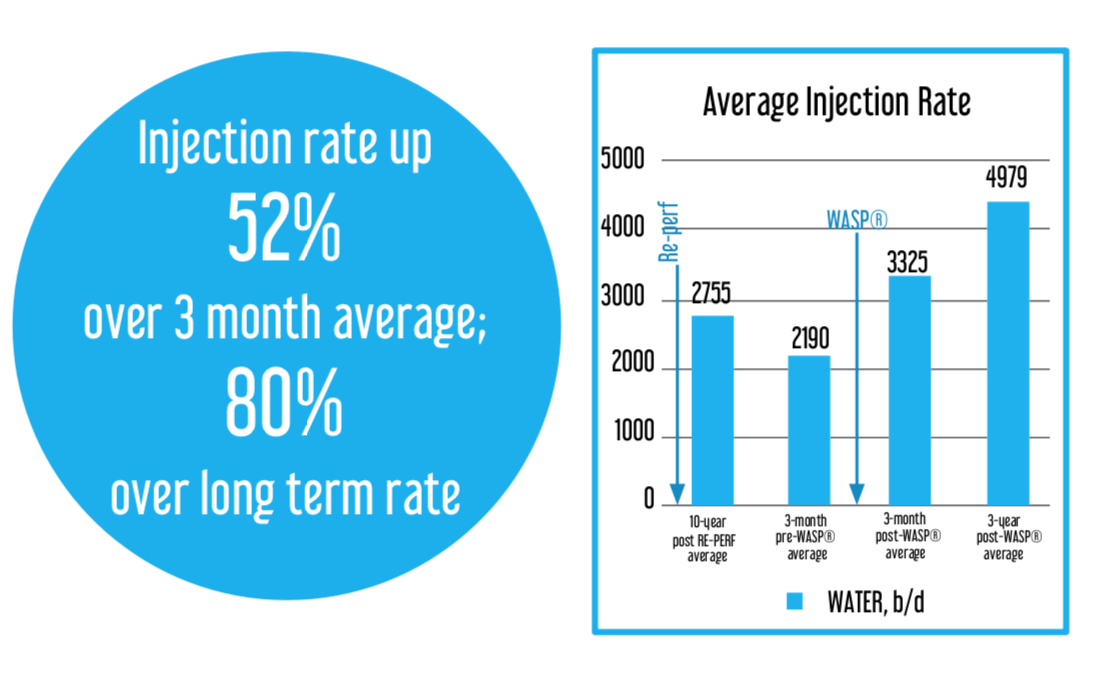

Public data for the BLUESPARK® treated well showed an average injection increase from 2,190 b/d to 3,325 b/d for 3-months post stimulation (52% increase).

Sustained injection over three years has averaged 4,979 b/d compared to the 10-years post re-perf value of 2,755 b/d (80% increase).

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.