NAM-SR-117 (Canada West)

CHALLENGE

Client determined that a reduction in total oil production from a producing well was due to scaling of a perforated interval in the Slave Point production zone. Indications of calcium carbonate (CaCO3) on both tubular and bottom hole pump were determined as the cause of the decreasing production.

Client required a cost effective remedial solution, in conjunction with a work over, to increase production. Client was seeking to deploy a technology that is simple, and that deals directly with the root cause of the decline – scaling and near-wellbore formation damage.

SOLUTION

Electro-hydraulic stimulation in cased hole applications.

Wireline deployed in conjunction with a workover on a producing well.

Completed BLUESPARK® treatment over the perforated zone of interest that had suspected scaling: Slave Point formation (dolomite/limestone).

BLUESPARK® treated the perforated interval of approximately 2.5 m (8 ft).

Ran production tubing and pump assembly into wellbore, monitoring production rates, pressures and fluid levels over the course of 90 days.

CONDITIONS

Slave Point limestone

Depth: 1800 m (5900 ft)

Temperature: 45 °C (113 °F)

OUTCOME

Significant inflow of oil was produced after the remediation.

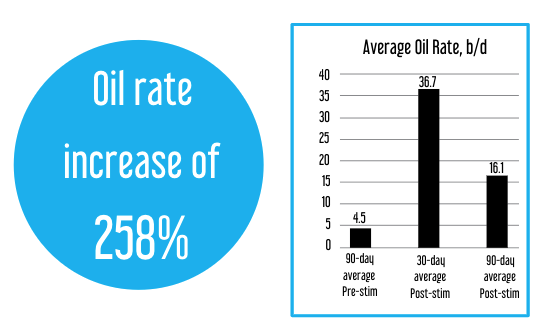

Client data shows an average oil production of 36.7 b/d over a one-month period (716% increase).

Sustained production over 90 days averaged 16.1 b/d of oil (258% increase).

Client is now evaluating the use of electro-hydraulic stimulation in other tight oil reservoir environments within the production pool for remedial interventions, in conjunction with workovers.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.