NAM-PW-108 (Canada West)

CHALLENGE

The clients’ well had initially been perforated and frac’d in the target zone. The well produced at 87% average water-cut for the first 2 years of production. Oil production was below other wells in the same pool and the well was shut-in.

The client was receptive to trying a new type of stimulation to remediate any near-wellbore damage that could be causing the production decline.

SOLUTION

Improve connectivity to the reservoir by using electro-hydraulic stimulation technology.

Sandstone reservoir was treated with BLUESPARK® after being shut-in for 10 months to re-initiate production.

No special tools or equipment were required on location to complete the remediation operation, other than third party E-Line.

Approximately 5 m (16 ft) of perforated interval were treated with our wireline conveyed tool in one 8-hour day.

Production rates and fluid levels were both monitored for comparison to pretreatment values.

CONDITIONS

Depth: 1,300 m (4,300 ft)

Temperature: 43 °C (110 °F)

OUTCOME

The well immediately produced oil at a higher rate that before being shut-in, with less water production.

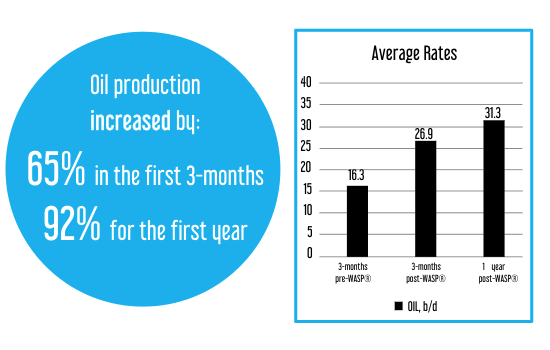

The oil production increased from 16.3 b/d to 26.9 b/d, comparing 3-month pre to post BLUESPARK®.

The 1-year post-BLUESPARK®production average was even higher at 31.3 b/d.

The water-cut for the 1st year post-BLUESPARK® was down 6%.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.