NAM-SR-109 (Canada West)

CHALLENGE

Client’s conventional oil well production rates had decreased by more than 60% in only 8 months. Root cause analysis, and previous data collected through solids analysis and visual characterization, concluded that a carbonate type scale was forming.

Since this was a low producer, a cost effective solution, in conjunction with a workover, was required to remediate the well. Identifying and utilizing an alternative cost effective technology that deals directly with suspected blocking mechanism (scale) in the wellbore and near-well reservoir.

SOLUTION

Electro-hydraulic stimulation in cased hole to improve well inflow.

In conjunction with a workover on the well to pull tubing and bottom hole pump assembly, BLUESPARK® was deployed.

Completed BLUESPARK® Treatment over the 3 m (10 ft.) perforated zone of interest – Gething Formation (sandstone).

Ran production tubing and pump assembly in wellbore and began monitoring production rates, pressure and fluid levels.

Immediate increase in production was observed.

CONDITIONS

Gething Sandstone

Depth: 1500 m (4900 ft.)

Temperature: 35 °C (95 °F)

OUTCOME

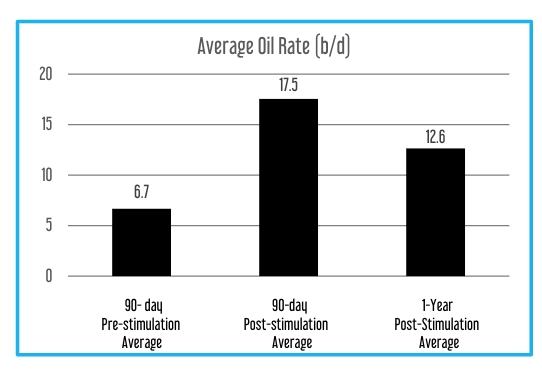

Oil production more than doubled after the remediation.

Client data shows an average increase in oil production of more than 10 b/d over a 3-month period (163% increase).

The data for the 1-year period post-stimulation showed a 90% increase in average production to 12.6 b/d.

Blue Spark Energy is paving the way towards a sustainable, dynamic oil & gas industry. As leaders in high-pulse powered wellbore remediations, we provide a revolutionary technology that is a safe, cost-effective, and efficient solution for forward-thinking energy providers.